|

ROCKSOLID POLYCURAMINE GARAGE COATING® ROCKSOLID POLYCURAMINE GARAGE COATING®

The Garage Coat, like all RockSolid Floors® Polycuramine™ coatings, offers unsurpassed durability. Polycuramine is 20 times stronger than epoxy. With its resistance to salt, oil, gas and other harsh chemicals, this is one of the toughest floor coatings on the planet. It's easy to maintain and will last a lifetime while still looking fantastic.

The zero VOCs in the RockSolid Polycuramine Garage Coat® also make it environmentally friendly, bringing the harmful chemicals involved to an absolute minimum. Even the packaging has been made environmentally safe, using pouches instead of cans. These pouches not only make it easier to work with, but also reduce waste sent to landfills.

It can be installed in temperatures between 0°F to 120°F (-18°C to 49°C), letting you apply it any time of year (most epoxy coatings require specific temperature ranges from 60°F to 80°F). Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. The RockSolid Polycuramine Garage Coat® works wherever you want, whenever you want. It can be installed in temperatures between 0°F to 120°F (-18°C to 49°C), letting you apply it any time of year (most epoxy coatings require specific temperature ranges from 60°F to 80°F). Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. The RockSolid Polycuramine Garage Coat® works wherever you want, whenever you want.

ROCKSOLID FOAM ROLLER™:

The specially-designed RockSolid Floors Foam Roller™, included in each Garage Coat kit, is the key to creating the exact thickness needed for optimal performance, providing the most professional finish available.

ROCKSOLID POLYCURAMINE CLEAR TOP COAT™:

RockSolid Floors Polycuramine Clear Top Coat™ is a clear high gloss protective coating that is formulated to offer unsurpassed durability. It is 20 times more durable than epoxy, ensuring that it won’t crack or peel and providing resistance to salt, oil, gas and other harsh chemicals. Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. RockSolid Polycuramine Clear Top Coat™ is recommended for the handyman’s shop floor, professional garages and other high traffic locations. The kit covers 250 sq. ft. over Garage Coat and Heavy Broadcast. RockSolid Floors Polycuramine Clear Top Coat™ is a clear high gloss protective coating that is formulated to offer unsurpassed durability. It is 20 times more durable than epoxy, ensuring that it won’t crack or peel and providing resistance to salt, oil, gas and other harsh chemicals. Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. RockSolid Polycuramine Clear Top Coat™ is recommended for the handyman’s shop floor, professional garages and other high traffic locations. The kit covers 250 sq. ft. over Garage Coat and Heavy Broadcast.

RockSolid Polycuramine™ is eco-safe and has zero VOCS and low odor, making it a great choice for indoor applications – it works wherever you want, whenever you want. RockSolid Polycuramine™ is eco-safe and has zero VOCS and low odor, making it a great choice for indoor applications – it works wherever you want, whenever you want.

GARAGE COAT APPLICATION:

|

Step 1: CONCRETE PREPARATION

Before any coating can be added, the pores of your concrete need to be opened up. Most floors are power-troweled before they're coated to smooth them out, which forms a micro-layer that closes these pores and keeps your Garage Coat from adhering properly. The RockSolid Floors Safe Etch™ (sold separately) solves this problem by breaking up this micro-layer and opening the concrete's pores. Simply mix it with water, pour it evenly on a 10' by 10' section of the floor, and scrub with a stiff bristle broom while it froths. Once the frothing stops, just rinse it off and move on to the next section until your entire floor is etched and ready for coating. Before any coating can be added, the pores of your concrete need to be opened up. Most floors are power-troweled before they're coated to smooth them out, which forms a micro-layer that closes these pores and keeps your Garage Coat from adhering properly. The RockSolid Floors Safe Etch™ (sold separately) solves this problem by breaking up this micro-layer and opening the concrete's pores. Simply mix it with water, pour it evenly on a 10' by 10' section of the floor, and scrub with a stiff bristle broom while it froths. Once the frothing stops, just rinse it off and move on to the next section until your entire floor is etched and ready for coating.

|

Step 2: MIX, SHAKE, and POUR

Thoroughly mix the material in all pouches by shaking it and squeezing each side of the pouch. Any clumps need to be massaged and broken up. Combine the two components by placing the pouch on the ground and rolling it from the Part A side towards the Part B side. This will create pressure in the Part A side and force the middle seal to burst, allowing the two components to mix together. Thoroughly mix the materials for at least one minute by shaking the pouch back and forth and squeezing the edges and corners towards the center of the pouch. Pour the mixed material from the pouch on the floor about a foot from the back corner wall in roughly 4’-5’ ribbons at least 2-3” wide. Cut in the edges with a paint brush. Thoroughly mix the material in all pouches by shaking it and squeezing each side of the pouch. Any clumps need to be massaged and broken up. Combine the two components by placing the pouch on the ground and rolling it from the Part A side towards the Part B side. This will create pressure in the Part A side and force the middle seal to burst, allowing the two components to mix together. Thoroughly mix the materials for at least one minute by shaking the pouch back and forth and squeezing the edges and corners towards the center of the pouch. Pour the mixed material from the pouch on the floor about a foot from the back corner wall in roughly 4’-5’ ribbons at least 2-3” wide. Cut in the edges with a paint brush.

|

|

Step 3: ROLL OUT Once a small amount of the Garage Coat is poured onto a section of floor, use the RockSolid Foam Roller™ to roll it out in an "M and W" pattern. A little bit goes a long way with the Garage Coat, so make sure to spread it in a thin layer. Continue to pour it in small amounts and roll it out as needed to cover the entire floor, then reseal the pouch and fold it in half. Because the Garage Coat is a two-part product, it won't cure until 8-10 hours after it is mixed and rolled out onto the floor. Once a small amount of the Garage Coat is poured onto a section of floor, use the RockSolid Foam Roller™ to roll it out in an "M and W" pattern. A little bit goes a long way with the Garage Coat, so make sure to spread it in a thin layer. Continue to pour it in small amounts and roll it out as needed to cover the entire floor, then reseal the pouch and fold it in half. Because the Garage Coat is a two-part product, it won't cure until 8-10 hours after it is mixed and rolled out onto the floor.

|

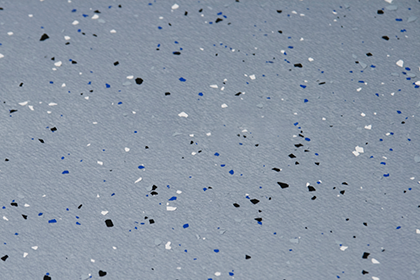

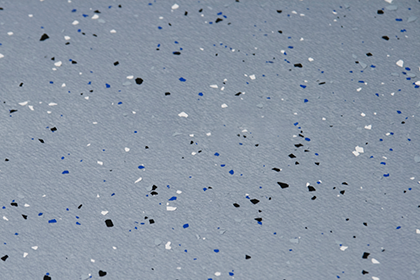

Step 4: BROADCAST Once you finish each strip of coating, you can start broadcasting the RockSolid Decorative Chips™ if desired. Grab small pinches of chip and throw them in the air over the wet Garage Coat. Be as consistent as you can with your broadcast throughout the floor for the most uniform finish possible. Leave a 6"-12" section near the next section to be coated free of chip to ensure your application is seamless. Once you finish each strip of coating, you can start broadcasting the RockSolid Decorative Chips™ if desired. Grab small pinches of chip and throw them in the air over the wet Garage Coat. Be as consistent as you can with your broadcast throughout the floor for the most uniform finish possible. Leave a 6"-12" section near the next section to be coated free of chip to ensure your application is seamless.

|

EVERYTHING YOU NEED COMES IN THE KIT:

|

- Instructional Booklet

- Citric-Etch Solution™

- Foam Roller

- Garage Coat Pouch

- Decorative Chip

|

Home | Brochures | Instructions | Store Locator | Main RockSolid Site

|

ROCKSOLID POLYCURAMINE GARAGE COATING®

ROCKSOLID POLYCURAMINE GARAGE COATING®

It can be installed in temperatures between 0°F to 120°F (-18°C to 49°C), letting you apply it any time of year (most epoxy coatings require specific temperature ranges from 60°F to 80°F). Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. The RockSolid Polycuramine Garage Coat® works wherever you want, whenever you want.

It can be installed in temperatures between 0°F to 120°F (-18°C to 49°C), letting you apply it any time of year (most epoxy coatings require specific temperature ranges from 60°F to 80°F). Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. The RockSolid Polycuramine Garage Coat® works wherever you want, whenever you want. RockSolid Floors Polycuramine Clear Top Coat™ is a clear high gloss protective coating that is formulated to offer unsurpassed durability. It is 20 times more durable than epoxy, ensuring that it won’t crack or peel and providing resistance to salt, oil, gas and other harsh chemicals. Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. RockSolid Polycuramine Clear Top Coat™ is recommended for the handyman’s shop floor, professional garages and other high traffic locations. The kit covers 250 sq. ft. over Garage Coat and Heavy Broadcast.

RockSolid Floors Polycuramine Clear Top Coat™ is a clear high gloss protective coating that is formulated to offer unsurpassed durability. It is 20 times more durable than epoxy, ensuring that it won’t crack or peel and providing resistance to salt, oil, gas and other harsh chemicals. Zero VOCs make it a great choice for indoor applications, especially when minimal to no odor is a must. RockSolid Polycuramine Clear Top Coat™ is recommended for the handyman’s shop floor, professional garages and other high traffic locations. The kit covers 250 sq. ft. over Garage Coat and Heavy Broadcast.

RockSolid Polycuramine™ is eco-safe and has zero VOCS and low odor, making it a great choice for indoor applications – it works wherever you want, whenever you want.

RockSolid Polycuramine™ is eco-safe and has zero VOCS and low odor, making it a great choice for indoor applications – it works wherever you want, whenever you want. Before any coating can be added, the pores of your concrete need to be opened up. Most floors are power-troweled before they're coated to smooth them out, which forms a micro-layer that closes these pores and keeps your Garage Coat from adhering properly. The RockSolid Floors Safe Etch™ (sold separately) solves this problem by breaking up this micro-layer and opening the concrete's pores. Simply mix it with water, pour it evenly on a 10' by 10' section of the floor, and scrub with a stiff bristle broom while it froths. Once the frothing stops, just rinse it off and move on to the next section until your entire floor is etched and ready for coating.

Before any coating can be added, the pores of your concrete need to be opened up. Most floors are power-troweled before they're coated to smooth them out, which forms a micro-layer that closes these pores and keeps your Garage Coat from adhering properly. The RockSolid Floors Safe Etch™ (sold separately) solves this problem by breaking up this micro-layer and opening the concrete's pores. Simply mix it with water, pour it evenly on a 10' by 10' section of the floor, and scrub with a stiff bristle broom while it froths. Once the frothing stops, just rinse it off and move on to the next section until your entire floor is etched and ready for coating. Thoroughly mix the material in all pouches by shaking it and squeezing each side of the pouch. Any clumps need to be massaged and broken up. Combine the two components by placing the pouch on the ground and rolling it from the Part A side towards the Part B side. This will create pressure in the Part A side and force the middle seal to burst, allowing the two components to mix together. Thoroughly mix the materials for at least one minute by shaking the pouch back and forth and squeezing the edges and corners towards the center of the pouch. Pour the mixed material from the pouch on the floor about a foot from the back corner wall in roughly 4’-5’ ribbons at least 2-3” wide. Cut in the edges with a paint brush.

Thoroughly mix the material in all pouches by shaking it and squeezing each side of the pouch. Any clumps need to be massaged and broken up. Combine the two components by placing the pouch on the ground and rolling it from the Part A side towards the Part B side. This will create pressure in the Part A side and force the middle seal to burst, allowing the two components to mix together. Thoroughly mix the materials for at least one minute by shaking the pouch back and forth and squeezing the edges and corners towards the center of the pouch. Pour the mixed material from the pouch on the floor about a foot from the back corner wall in roughly 4’-5’ ribbons at least 2-3” wide. Cut in the edges with a paint brush. Once a small amount of the Garage Coat is poured onto a section of floor, use the RockSolid Foam Roller™ to roll it out in an "M and W" pattern. A little bit goes a long way with the Garage Coat, so make sure to spread it in a thin layer. Continue to pour it in small amounts and roll it out as needed to cover the entire floor, then reseal the pouch and fold it in half. Because the Garage Coat is a two-part product, it won't cure until 8-10 hours after it is mixed and rolled out onto the floor.

Once a small amount of the Garage Coat is poured onto a section of floor, use the RockSolid Foam Roller™ to roll it out in an "M and W" pattern. A little bit goes a long way with the Garage Coat, so make sure to spread it in a thin layer. Continue to pour it in small amounts and roll it out as needed to cover the entire floor, then reseal the pouch and fold it in half. Because the Garage Coat is a two-part product, it won't cure until 8-10 hours after it is mixed and rolled out onto the floor. Once you finish each strip of coating, you can start broadcasting the RockSolid Decorative Chips™ if desired. Grab small pinches of chip and throw them in the air over the wet Garage Coat. Be as consistent as you can with your broadcast throughout the floor for the most uniform finish possible. Leave a 6"-12" section near the next section to be coated free of chip to ensure your application is seamless.

Once you finish each strip of coating, you can start broadcasting the RockSolid Decorative Chips™ if desired. Grab small pinches of chip and throw them in the air over the wet Garage Coat. Be as consistent as you can with your broadcast throughout the floor for the most uniform finish possible. Leave a 6"-12" section near the next section to be coated free of chip to ensure your application is seamless.